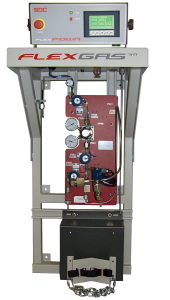

FlexGas™ Cylinder Gas Rack

Sister product and a non-hazardous counterpart to the widely successful FlexGas™ UHP gas cabinet, the FlexGas™ Gas Rack is designed to cover the widest range of cylinder gas storage & delivery applications. SDC®, a time-proven manufacturer of safe, high quality non-haz gas farm & gas cylinder delivery systems for the 1st-Tier semiconductor industry, has seen the need for similarly safe & clean systems in other industries. As codes, local regulations and insurance guidelines tighten, more sophistication and control is required from what was once a “strap a cylinder to the wall” philosophy. The SDC® branded modular design concept allows the customer to tailor each system to meet their safety, process, purity, and budgetary goals.

The simplest industrial shop system may be configured with a 1-Valve brass gas panel in an exhausted enclosure. More complex systems may include up to 3 UHP grade gas panels with manual PURGE/EVAC capability, gas leak detection & ESO control.

FlexGas™ makes it easy to meet your exact gas delivery needs. Our modular design concept allows you to use a building-block method to configure a gas cabinet to your specifications. No more paying way too much for a system that far-and-away exceeds your requirements. Start by choosing one of several rack configurations. Begin customizing right at the gas panel level by selecting the gas panel purity. From the standard 3-Valve UHP panel, you can choose to add PURGE capability (4- Valve) or PURGE/EVAC capability (6-Valve). Add safety and peace-of-mind by purchasing the optional FlexPowr™ Controller. Simply select which panels you want to shut down on alarm, and they will be fitted with a normally-closed ESO Valve for automatic shutdown. The ESO Controller supports up to 12 discrete input signals in which 10 are user settable and 4 grouped relay output alarm signals in which 2 are user settable. Also, Modbus TCP allows remote reading of alarm & panel status, weights, etc.

FlexPowr™ Control Features

- Touch Screen Display

- Up to 10 user-definable alarm inputs

- Up to 2 user-definable outputs

- 8 spare “user configurable” INPUTS

- 8 spare “user configurable” OUTPUTS

- EMO button

- Exhaust pressure switch

- HI cylinder pressure switch

- HI delivery pressure switch

- Integrated gas leak detection

Process Panel Features

- UHP: panels & manifolds are orbitally welded/VCR® construction, 316L SS [20Ra]

- 3-Valve design [HP vent]

- 4-Valve design [adds PURGE]

- 5-Valve design [adds LP VENT]

- 6-Valve design [adds EVAC]

Standard Configurations

- 2-cyl, [1-process, 1-purge]

- 2-cyl, [2-process]

- 3-cyl, [2-process, 1-purge]

Dimensions

- 1-cyl: 24”W x 72”H x 17”D

- 2-cyl: 24”W x 72”H x 17”D

- 3-cyl: 36”W x 72”H x 17”D

Options

- 10 Ra surface finish

- Dual stage regulators

- Outlet filters

- DISS cylinder fittings

- Adjustable cylinder shelves

- Restrictive flow orifices

- Cylinder scales

- CGA torque wrenches

Codes and Standards

Exhaust Specifications & Requirements

| 1CDA | adjustable to 90 psig | 1 slm max. |

| 2Purge N2 | adjustable to 85 psig | 85 slm max. |

| 3Venturi N2 | adjustable to 60 psig | 30 slm max. |

| Process Vent | >1.0" WC | 100 slm |

| 1Power | 110V, 3A | N/A |

1Needed only with optional ESO Controller

2Needed only with 4-Valve, 5-Valve, 6-Valve gas panel configurations

3Needed with 6-Valve gas panel configuration